Machining Capability

Machining Capability

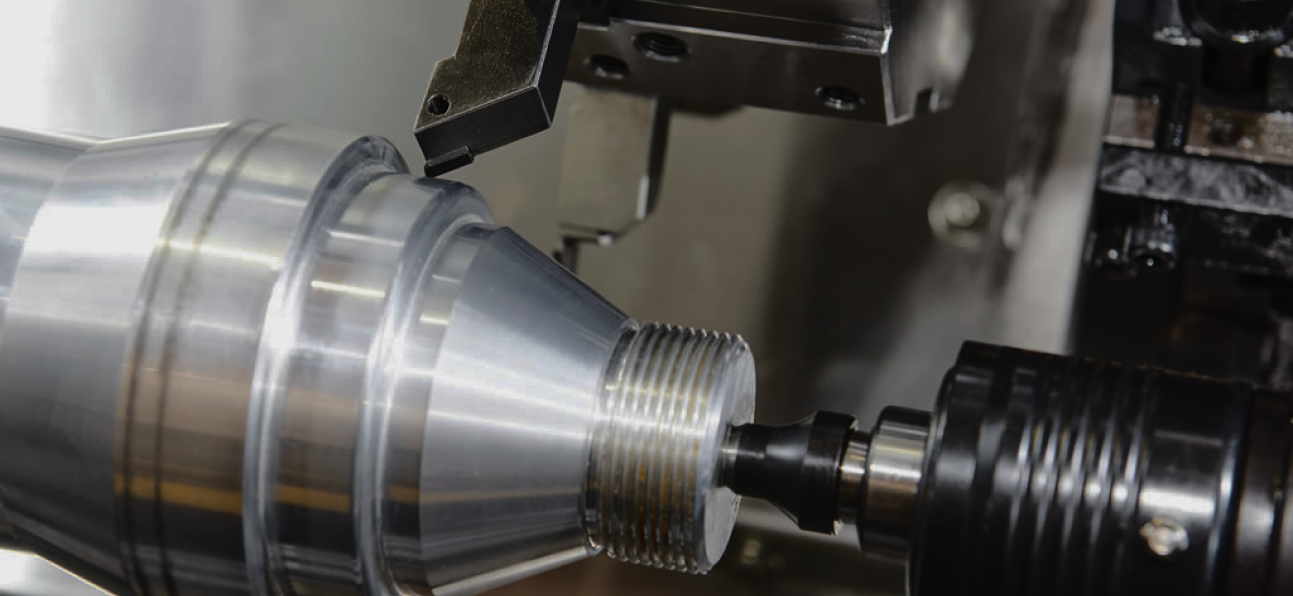

Vraj Impex manufacturing capabilities encompass the entire gamut of precision engineering products. The synthesis of best-of-the breed machinery, technically qualified professionals and a quality-driven management policy transforms the most complex engineering drawing into a high-quality product.

The Machine shop layout has been designed to suit the line concept for mass production as well as batch production. Vraj Impex offer an array of CNC Turning Centres, CNC Vertical Machining Centres with 4th Axis facilities along with the latest control systems for production jobs.

Machining Capability

- Machining of Ferrous & Non Ferrous Materials like Carbon, Stainless & Mild Steel, Aluminum alloys & Copper alloys.

- Machining jobs with batch sizes 5 nos. to 50000 nos.

- Core competence in Bar stock turning of any material.

- Machining of Hardened Steel up-to 50 HRC.

- Machining of Shafts(Turning, Keyway, Grinding & Burning etc.)

- Machining of Forging made of Mild, Carbon, Stainless steel, Aluminum & Copper alloys.

- Machining of Investment Casting, Sand Casting as well as Shell Molding casting.

- Grinding external & internal up-to precision levels of 7 um.

Manufacturing Process Supports

Ability to build up manufacturing process fixtures & special tools in house with strong back up of designing. New product design and development time is minimum as proactive approach of well experienced engineers.